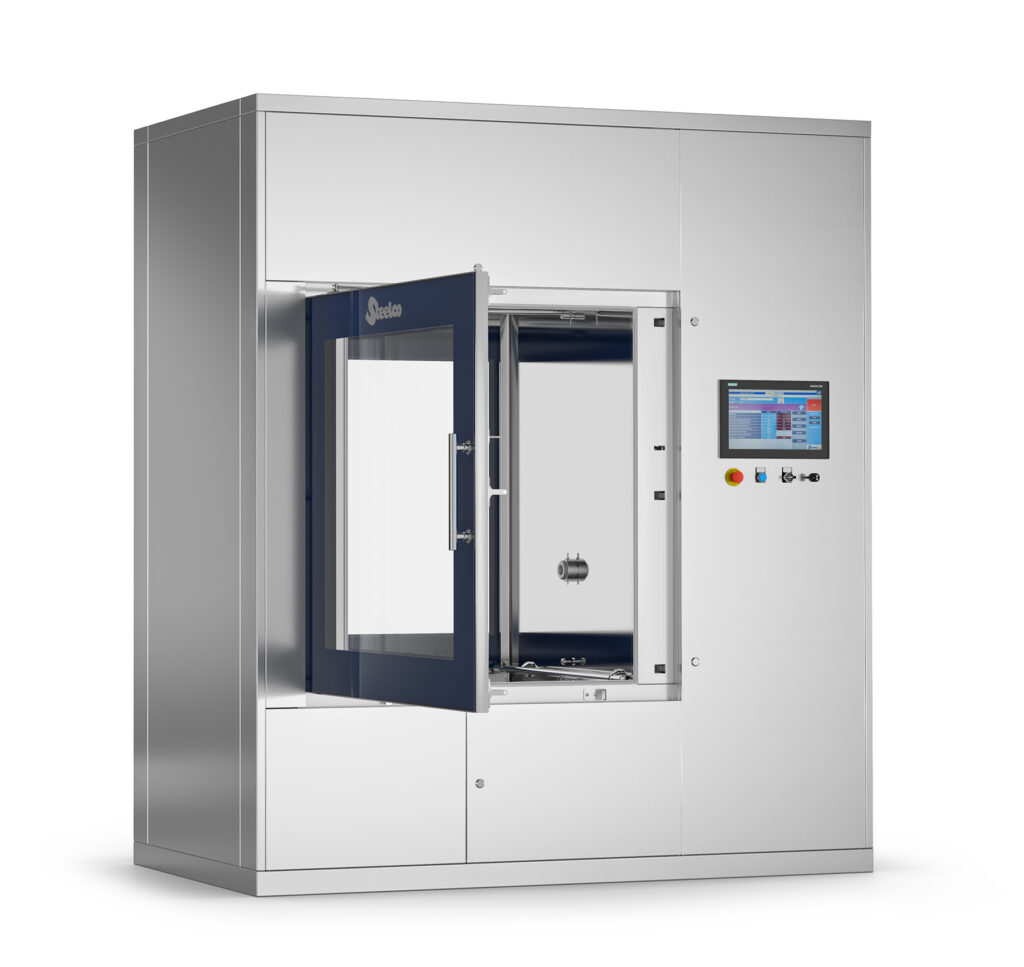

Exhibit 6 — DS Optima PH Washer & Specially Designed Washing Cart

DS Optima – Pharma Grade Parts Washer is designed for validatable cleaning and optimal throughput of materials and components used in Bio-Pharmaceutical manufacturing in the smallest available footprint of valuable GMP manufacturing space.

DS Optima – Pharma Grade Parts Washer is designed for validatable cleaning and optimal throughput of materials and components used in Bio-Pharmaceutical manufacturing in the smallest available footprint of valuable GMP manufacturing space.

The design ensures self-cleaning of the machine chamber and pipework at each process stage, to prevent cross contamination risk. It can be configured in different layout: single or passthrough double door version with hinged full glass door. The technical area can be on right or left side. The heating elements, located in the sump, are pharma industry compliant, sanitary and dead leg free, fabricated from AISI 316L (1.4404) stainless steel and electro-polished. They may be connected to plant steam in the Steam heat exchanger version or directly to plant power in the Electrical heat exchanger version.

Drying phase assure the complete drying of the items loaded into washing chamber, both internal and external surface. The electrical heating elements enable variable drying temperature control. The HEPA filter is placed in line at the end of the drying path before entering the chamber and rack.

DS Optima PH is designed, manufactured, validated, and documented according to the latest global practices and standards to facilitate customer compliance with current Good Manufacturing Practices (cGMP’s).

This exhibit will also include a specially designed washing cart. Please click here to read more about this cart.

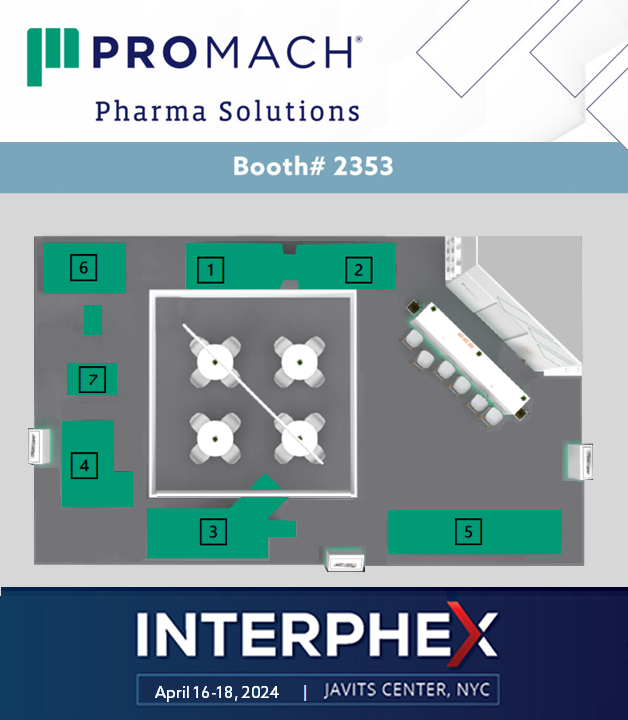

Please use the map, legend, and links below to familiarize yourself with the technologies we will be exhibiting.