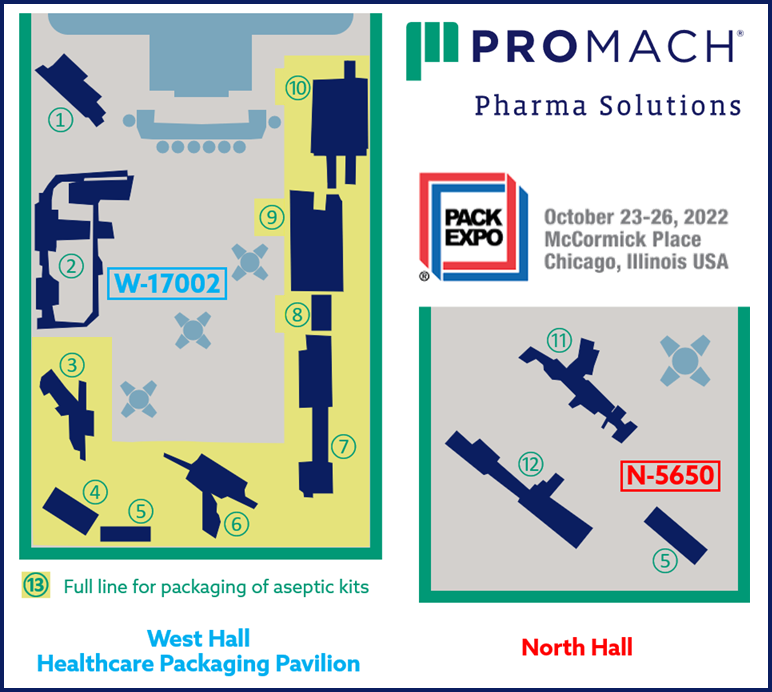

Exhibit 13 — Full line for packaging of aseptic kits

ProMach’s Pharma business unit showcased their integration capabilities at Pack Expo by exhibiting a turnkey packaging line, which included all equipment from vial and syringe filling to case packing, at booth #W-17002 in the Healthcare Packaging Pavilion. We were excited to demonstrate this complete solution, from filling to point-of-use.

From processing solution design to the end of the packaging line, ProMach is an extensive provider of best-in-class solutions to maximize production line performance. This fall at Pack Expo, not only did we exhibit Standalone Machines and Cellular Integrated Systems, but we also presented this Complete Turnkey Blister Packaging Line for aseptic kits. Customers had the unique opportunity to see and learn about ProMach Pharma’s best-in-class solutions for filling, labeling, and packaging vials, syringes, bottles and more. This was a great opportunity to see the versatility of solutions offered by ProMach Pharma in a real-world scenario.

ProMach Pharma’s turnkey blister packaging line for aseptic kits on exhibit at Pack Expo began with Dara’s NFL/2 system filling and closing ready-to-use syringes and vials. NJM’s Courser 230 labeled the syringes and WLS’ VR-72 labeled the vials. A robotic pick-and-place from PharmaMed fed one syringe and one vial per cycle to Pharmaworks’ TF2 blister machine. These blister-packed kits were then conveyed on the XTS linear transport to a Serpa P100 horizontal cartoner, followed by a Serpa P200 case packer. Labels for syringes and vials were printed off-line with WLS’ Autonomy digital label printer.

Please use the map, legend, and links below to familiarize yourself with the technologies we exhibited.