![]()

Upgrades available for the Cremer CF1220/1620 Single/Double/Quad

NJM is the exclusive representative and sales resource for Cremer tablet counters in the US and Canada. Find below all of our aftermarket upgrades and obsolescence replacements available for the Cremer CF1220/1620 Single/Double/Quad models.

Mouse over or click any of the highlighted areas on the machine to learn more about the aftermarket products available.

–

–

–

HMI upgrade (Highly recommended)

The “10 inch” and “master terminal” HMI are no longer supported/available and must be upgraded to the 15-inch screen package.

Benefits:

- Much more reliable

- Hardware that is supported and highly available

- Windows 10 Platform with up-to-date security

- 21 CFR Part 11 compliant

- Larger screen (15 inch) for improved operating efficiency

- Possibility of adding the following options: OPC-UA and LDAP

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Software System Upgrades

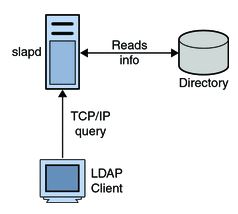

LDAP software upgrade

Use the company network Lightweight directory to create new users or modify access right to existing users/machine operators.

Benefits:

- Better managements of machine operator rights

- Better security

OPC-UA Software upgrade

With the OPC-UA software upgrade, customers interested in implementing OEE to promote efficiency are able to read some values from the tablet counter to display status or statistics. The OPC-UA option is available to help in making this project come to life.

Software and language upgrade

Upgrade the machine from an HHT to the latest version of a 15inch HMI.

Benefits:

- Data and security access

- Machine and operator efficiency increase

- Access to the latest diagnostics features

- Backup and new functionality

- LDAP and OPC-UA ready

Back to overall machine diagram ↑

–

–

–

–

–

–

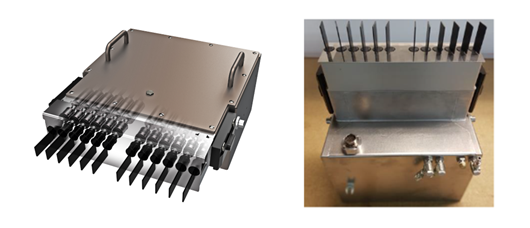

Memory flap servo upgrade

When upgrading memory flaps of the CF1220, you increase accurate counting and reliability and reduce maintenance time of cylinders and solenoid valves. This servo memory flap upgrade will help reduce maintenance to a minimum.

Benefits:

- Much more reliable

- Considerable reduction in maintenance

- High count accuracy

- Minimal part replacement

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

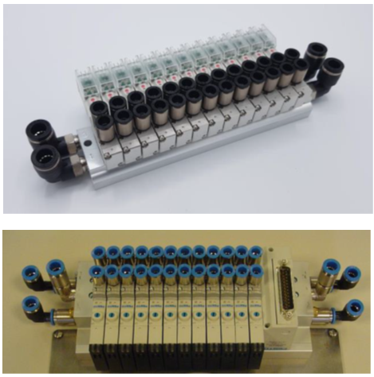

Memory flap solenoid valve and cylinder obsolescence (Highly recommended)

Cremer manufactures an excellent product but, unfortunately, they are not immune to component obsolescence. A large quantity of memory flap units now have obsolete solenoid valves and cylinders. Long and unplanned down time can be reduced when upgrading your memory flap units.

Benefits:

- Highly available replacement parts

- Reliability and accurate count. Your unit will run as if it was brand new!

- Prevent long and unplanned costly downtime

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Conveyor gating solenoid valve obsolescence (Highly recommended)

Many older machines have old and obsolete gating solenoid valves. When valves wear, they tend to react slower and sometimes do not react at all. To prevent unplanned downtime, this upgrade is a must.

Benefits:

- Reliability

- Highly available replacement parts

- Prevent long and unplanned costly down time

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

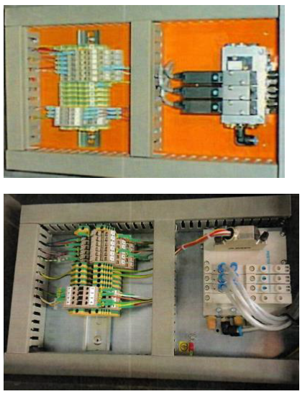

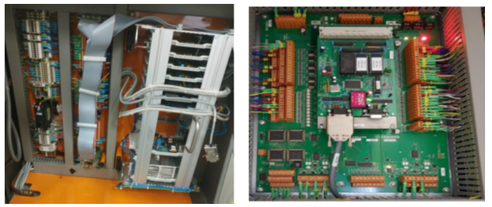

Machine controls upgrade

Many machines in the field have the old 8-bit control system. Many components are obsolete, and the system is difficult to maintain. This upgrade will provide the latest control version as well as the latest 15-inch control HMI by default.

Benefits:

- Highly available control components

- Reliability

- Prevent long and unplanned costly down time due to unavailable parts

- Windows 10 security

- Upgrade ready for OPC-UA and LDAP

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Machine power side component obsolescence

Older machines in the field have obsolete power components like contactors, security module, power supplies and especially the AC drives. This improvement will reduce long and unplanned downtimes while upgrading those power components.

Benefits:

- Highly available power components

- Reliability

- Prevent long and unplanned costly down time due to unavailable parts

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Reject system

Double stack or broken tablets can lead to “Miscounts.” Special trays with the reject system can improve the quality of the product sold.

Benefits:

- Save on additional tablets in bottles due to undetected “overstack”

- Delivery of better quality due to reduction tablet pieces in bottles

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Funnel blockage verification

Occasional funnel blockage and disturbed production can be reduced when using this optical verification system. When a blockage is detected, an up/down movement of the funnel will attempt to unblock them.

Benefits:

- Reduce downtime

- Reduce messy blockage

- Reduce possibility of breaking funnels

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Reject confirmation sensor

Make sure rejected bottles go onto the reject table and actually do not end up down the line. Bad setup or defective reject cylinder may allow a rejected/empty bottle to end up in the good product lane. Make sure this does not happen using the optional reject confirmation sensor.

Benefits:

- Capture unqualified product

- Quickly find out about a defective reject device

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–