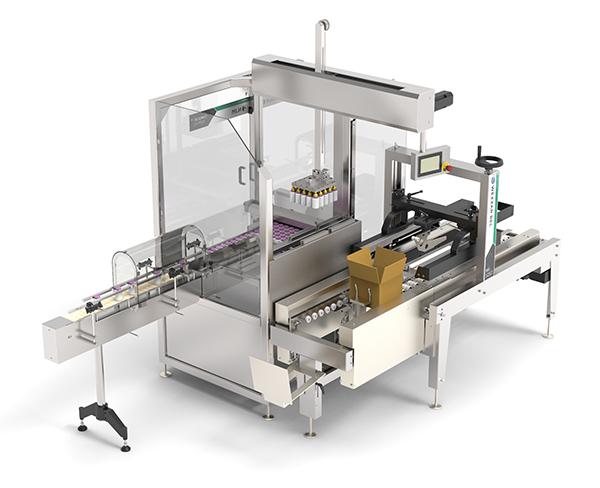

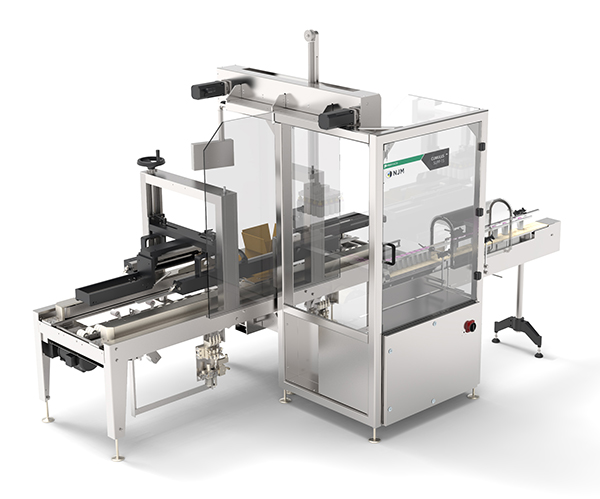

As track-and-trace deadlines loom, pharmaceutical manufacturers and contract packers both big and small are rushing to get their serialized packages aggregation-ready. To help our customers prepare, NJM and the ProMach Innovation Center are hard at work developing new equipment that makes the process fast, simple and affordable. Their latest case packer solution – the semi-manual Cumulus Model SLPP-15 Case Packer, debuting next month at Interphex booth #2353.

As the smallest and most affordable case packing station currently on the market that satisfies upcoming aggregation legislation, the Cumulus is perfect for manufacturers and packers who want to quickly and easily add traceability while automating end-of-line processes to increase productivity.

The high-performance Cumulus Model SLPP-15 Case Packer features a servo-driven, two-axis pick and place robot that packs up to 10 cases per minute. The cases are packed with up to 180 bottles per minute, depending on the number of layers and bottles in the case. It handles round and rectangular bottles and can quickly be changed over to handle a new bottle and case size with no tools required.

Combining best-in-class solutions from NJM and Wexxar Bel, the versatile Cumulus can package OTC pharmaceuticals, nutraceuticals, cosmetics, foods and beverages and other products. To package regulated pharmaceuticals, serialization and aggregation options from OPTEL can be added.

Read the recent press release to learn more about the Cumulus Model SLPP-15 Case Packer.

If you’re headed to Interphex next month, visit the ProMach Pharma Business Line at booth #2353 to speak with our team and check out equipment like the WLS LP-100R label printer, the Dara SX-310-RDL filling and closing machine for vials and much more.