The following article appeared in the January/February 2021 edition of Healthcare Packaging. The entire edition can be read online here.

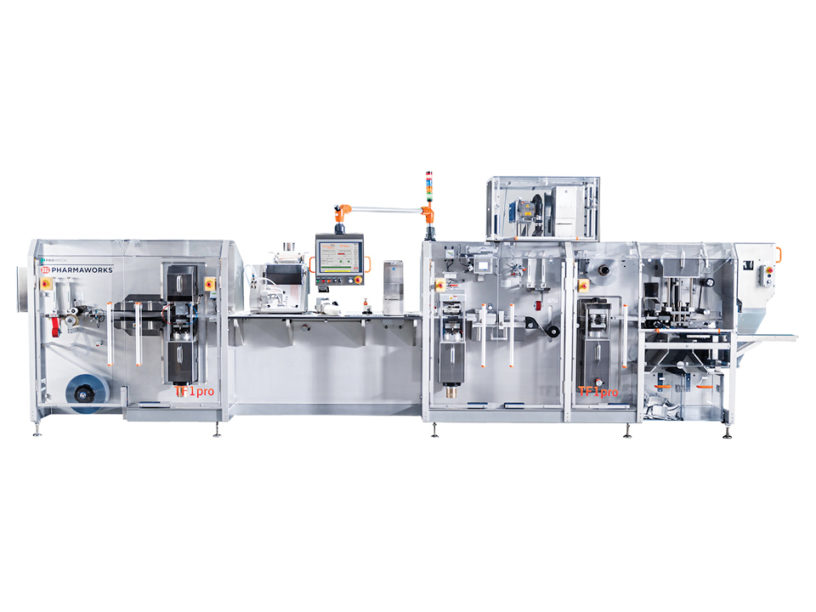

Pharmaworks, part of ProMach Pharma Solutions, introduced at PACK EXPO Connects the TF1pro, the next-generation system in its TF1 family of compact blister machines. The system is particularly suited to small to moderate batch sizes and clinical trials for pharmaceutical and biotech manufacturers and contract packers that frequently change over. The fully servo-driven blister machine runs up to 100 indexes (200 blisters) per minute.

While smaller systems don’t always have the bells and whistles of high-throughput machines, Pharmaworks added many features to maximize product safety and ease of cleaning, while also achieving fast changeovers, accuracy, and versatility. Ben Brower, general manager at Pharmaworks, said, “Two years ago, a large pharmaceutical company approached us and asked us to develop a compact blister machine with the most advanced cGMP features. With their design input, we developed the TF1pro, the only blister machine on the market that offers this high level of product safety and sanitation in a small footprint.”

The system accommodates tablets, capsules, softgels, vials, syringes, liquids, and more. The intermittent-motion TF1pro supports both thermoforming and cold forming applications and runs a wide range of base materials with a standard roll diameter of 500 mm, providing twice the production capacity of the TF1E blister machine. The usable forming area is 120 by 165 mm with a depth of 25 mm. Optional product vision inspection and print vision inspection are available, as well as full serialization if needed.

Processes and parameters—including temperature, pressure, and the timing of each step—are PLC-controlled and programmed as a unique recipe in the TF1pro’s large HMI. The TF1pro offers either Rockwell Automation or Beckhoff control systems.

As the base roll unwinds, an optional feature monitors roll diameter and alerts the operator when it’s time to add fresh material at the splicing station. Power-driven rollers form a loop in the material, while a sensor ensures that the material loop is in the correct area. This touchless feature helps prevent excess drag on the material, meaning less stretch, saving on costs by allowing the use of small width base rolls.

Next, a splice detector notifies the operator when there is a splice in the web, allowing the machine to track the splices and automatically reject that section of material.

The company reports that automated adjustment of heating plates, forming tools, and other change parts translates into a 30% reduction in changeover time versus other TF series machines. It features ergonomic components that slide in and lock, including the guide track on the feeding station. The heat area automatically retracts when not in use for operator safety and convenience during changeovers and maintenance.

Sloped surfaces throughout the system eliminate the chance of cross-contamination from trapped product or debris, which also speed changeover by simplifying machine cleaning.

At the heating station, upper and lower plates apply contact heating to the base material. The heating station opens fully during machine stop to remove heat from the material. There are optional burnout detectors to determine that all heating elements are working correctly—these will stop the machine if an issue is detected.

The warmed material is then indexed to the forming station where upper and lower tools create blisters of predetermined shape, size, and depth. These are change parts that permit toolless changeover, depending on the blister dimensions needed.

Driven by a servo motor, the lower tool moves upward during the forming process and this travel can be changed and stored on the HMI to allow the most efficient motion for a given blister size. The blister cavity can be formed with air only or air plus plug assist (for cavities up to 25 mm deep).

The TF1pro is available with a wide variety of options, including selective forming that enables specific pockets to be turned on and off within the same tool. Pinhole detection for the lid material and/ or the base material is available for cold forming. Additional options include a lid material splice table, a splitter, servo plug assisted cold forming, and both helium and nitrogen gas flushing.

Finished blister cavities are indexed to the feed area, a separate module on the TF1pro that can be tailored to almost any length needed up to 2,500 mm. Open access from the front and rear in combination with feed area length allows automatic feed systems to nimbly dock and undock as needed or allow operators to manually fill blister cavities.

Pharmaworks offers several feed systems for its blister packaging machines. The machine on show used the FA1 feeder (also common are the FF1 and FT320) with servo-driven technology to pick and place product into blister cavities. This next generation FA1 feeder is enhanced for more reliable pick motion and features that help speed cleanup and enable toolless installation.

At the feeding stage, product is conveyed across a vibratory sift tray, where dust and debris are removed and product is aligned in the feed track. The product populates each groove in the slanted track, enabling gravity to pull the product down the track. The end point of each groove is pre-engineered to match the blister cavity orientation on the web. (When feeding is done manually, operators can work from either side of the machine.)

Before the blisters arrive at the seal station, the TF1pro’s advanced vision system inspects the product shape and color, and checks for broken or missing product. The vision system logs this information on good and bad blisters into the blister tracking register (BTR). The position of bad blisters on the web is identified, and these products will be rejected later.

Lidding may be preprinted or printed online with the required lot and date codes. Several third-party printers are compatible with the system while a Scanware print vision system checks and logs print quality.

To ensure consistent and accurate seal integrity, a load cell provides real-time information on seal pressure. A secondary high-speed sensing system will detect any foreign object between upper and lower seal plates. If an object is detected, the sealing cycle will instantly stop and reverse plate travel. Another safeguard on the TF1pro is a retracting seal plate—if web motion stops, the upper seal plate retracts to the rear so that the web won’t be exposed to unnecessary heat.

The blisters are then perforated and die cut by the inverted die punch. The reject/transfer station uses a vacuum arm to lift the “good” blisters onto the outfeed conveyor while “bad” blisters simply drop down into the reject bin, which ensures consistent and accurate ejection. Positioning the die cutter in this way also provides space at the end of the web for direct coupling of a cartoning machine. Blisters can be manually packed as well.

Check out the many packaging solutions featured by Pharmaworks at their PACK EXPO Connects Virtual Showroom, found at PE.show/211.