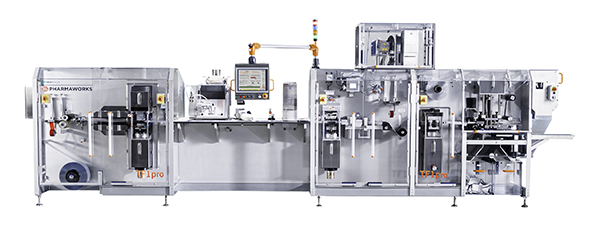

Pharmaworks is famous for their best-in-class blister machines for the pharmaceutical and biotech industries. Last week, the newest member of ProMach Pharma Solutions announced the TF1pro, the most sophisticated system in their popular TF1 family of compact blister machines, which debuts at the Pack Expo Connects virtual show next week.

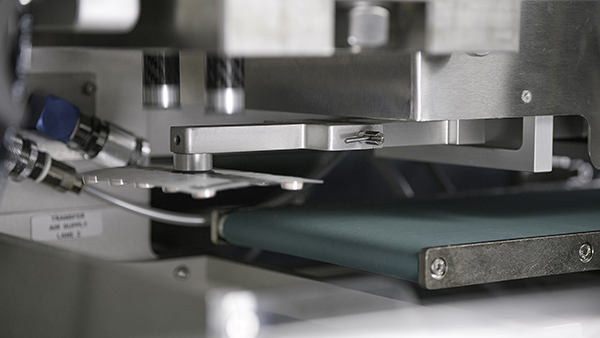

Designed to maximize product safety and ease cleaning, the TF1pro offers sophisticated cGMP features including sloped surfaces, a positive reject / transfer station, overload detection and an enclosing for base material. It’s ideal for manufacturers and contract packers with medium and small batch sizes, since it features a compact footprint, runs up to 100 indexes (200 blisters) per minute and changes over in less than 10 minutes with no tools required.

Fully servo-driven, the intermittent motion TF1pro supports both thermoforming and cold forming applications and is compatible with all corresponding materials. It is suitable for tablets, capsules, softgels, vials, syringes, liquids and more.

Pharmaworks can customize the TF1pro with a wide variety of options including different feeders, accessories and floor plans as well as selective forming, low level detection alerts and pinhole detection.

“The TF1pro is not a typical blister packaging machine,” said Ben Brower, Director of Sales and Marketing at Pharmaworks. “There’s a reason we call it the ‘pro’ – it comes with all the latest bells and whistles.”

Read the press release to learn more about the TF1pro. Plus, join the live Pack Expo Connects virtual demos on Mon, Nov 9 at 1pm CST and Tues, Nov 10 at 10:30am CST to see the TF1pro in action.