Versatility – it’s a hot topic these days. More and more of our customers are asking for highly flexible, low-volume packaging equipment that can quickly adapt to different types of packages and products. To meet this demand, NJM has launched several versatile systems in the last year including the Model 403 Final Touch print & apply labeler for secondary packages and the Trotter Model 127 pressure sensitive labeler for round, square, rectangular and oval bottles. Now, we’re offering our customers the all-new Courser 230 vial/syringe labeler.

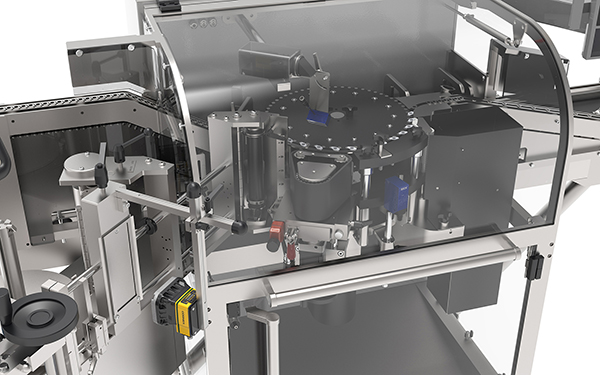

What makes Courser unique is its dual-purpose design. This compact labeler can be built to handle both vials and syringes or dedicated to one, with the option to later modify the system in the field. Actually, NJM can configure each Courser to label even more than vials and syringes, including bottles, ampules, cartridges, centrifuge tubes, auto-injectors and other small or unstable packages. By enabling a wide variety of packages to be labeled on a single machine, Courser reduces floorspace requirements and the cost of investment.

Ideal for pharmaceutical manufacturers, contract packers, 503B pharmacies, biotech companies and others, Courser can be designed with a manual infeed and discharge or integrated into a fully automated line to meet the needs of each customer. It’s perfect for small production runs, offering speeds of up to 250 vials per minute and 200 syringes per minute. Applying clear and opaque plastic, metallic and paper labels, Courser achieves a placement accuracy of +/- 1/32 inches (1mm). Changeover is fast too – it can be switched to handle a new package type and/or size in 10 to 15 minutes with minimal adjustments and no tools required.

If you’re heading to Pack Expo this month, visit the ProMach Pharma Business Line at Healthcare Packaging Expo booth N-307 to see the Courser 230 on exhibit and speak with a member of our team.